Advanced Industrial Composites

The use of manufacturing aerospace composites is growing rapidly, led by major airframe manufactures for both commercial and military aviation. Advanced aerospace composites have gained wide acceptance to replace metal, primarily for weight reduction. Performace benefits of the use of composites include loweringfuel costs, increasing flight time, speed, and distance.

The advantages of using advanced composites in these applications include:

- The ability to leverage directional fiber strength

- Corrosion resistance

- Light-weight materials

- Fatigue performance

- Damping properties

- Electrical insulation

Composiflex Supports

The support industrial composite customers, Composiflex offers:

- Proprietary FlexPLY™ materials

- Industry leading proven solutions

- Several thickness options

- Customized solutions are cut to size with predrilled attachment holes

- Part marking options are available

Many advanced industrial applications benefit from improved directional stiffness, electrical insulation, damping, and fatigue performance.

Applications

The applications that Composiflex supports include:

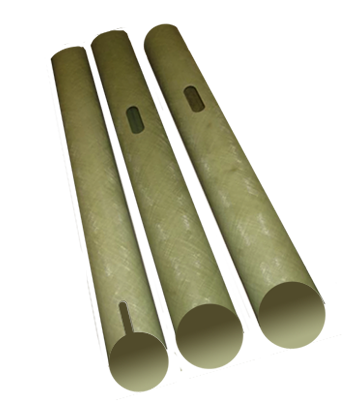

- Industrial Automation bars and booms (including robot arms)

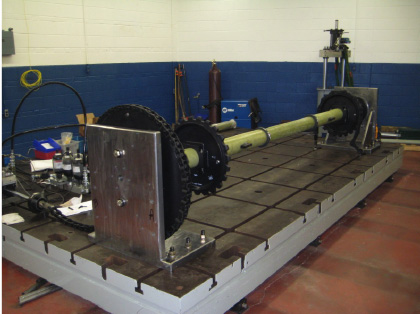

- High-torque industrial shafts

- Drive shaft coupling components for wind turbines and other applications

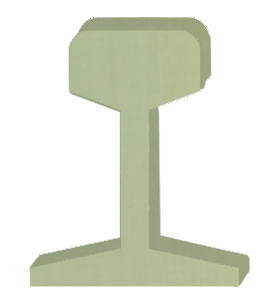

- Railroad insulated rail joints

- Filament over-winding of rotors and magnets